European Federation of Corrosion (EFC)-Newsletter

The mCBEEs Innovative Training Network (ITN) PhD

students (Live Mølmen (Department of Electrification and

Reliability, Research Institutes of Sweden), Salil Sainis

(Department of Materials and Manufacturing, Jönköping

University) and Sabrina Patricia Rosoiu (Center for Surface

Science and Nanotechnology, University Politehnica

of Bucharest) produced a total of fourteen videos (2-5

minutes each) describing the corrosion problems they are

working on, and how they are helping solve these problems

(Fig. 5). These were posted on YouTube as well as on the

mCBEEs website, Facebook, Twitter and LinkedIn pages,

the students own personal accounts, and the common

accounts for all Marie Skłodowska-Curie Actions. On

the mCBEEs website, the videos are sorted according to

application areas: modelling, energy conversion, electronics

and biocompatible materials. As well as helping to spread

awareness of the corrosion awareness day, the videos are

a great tool for our students to disseminate their personal

projects. For more information on the mCBEEs initiative,

please visit their website (www.mcbees.eu).

Scientific conferences 2018-2019

Eurocorr 2019, Seville

Abstract

Ni-Sn alloy/ rGO composite coatings involving deep eutectic solvents – Evaluation of corrosion behavior

Sabrina Patricia Rosoiua, Aida Ghiulnare Pantazia, Aurora Peticaa, Anca Cojocarua,b, Stefania Costovicia, Teodor Visana,b, Liana Anicaia, Marius Enachescua

aCenter of Surface Science and Nanotechnology, University Politehnica of Bucharest, Splaiul Independentei 313, Bucharest, 060042, Romania

bDepartment of Inorganic Chemistry, Physical Chemistry and Electrochemistry, Faculty of Applied Chemistry and Materials Science,University Politehnica of Bucharest, 132 Calea Grivitei, Bucharest, Romania, 010737, Bucharest, Romania

Graphene related materials are attracting the current interest owing to their unique electrical, thermal and mechanical properties. Metal-graphene composites have great potential in the electronic field because they exhibit superior properties. The incorporation of graphene/GO into the metallic matrix could induces changes in the morphology and microstructure of the coating. In addition, the presence of the graphene sheets could improve the corrosion resistance, since they could act as a barrier to the aggressive environment, hindering the interaction between the corrosive ions and the metal matrix slowing down the corrosion rate. Nickel tin alloys have been used in printed boards circuits mainly due to them etch resistivity and the ability to prevent the growth of Sn whiskers, which are responsible for short circuits. The electrodeposition of the composites from aqueous electrolytes, which is commonly used, is limited by the electrochemical potential window. To overcome this disadvantage, deep eutectic solvents (DES) represent a promising alternative. Moreover, the ionic liquids were found to be a suitable media to stabilize the graphene/CNTs dispersions avoiding agglomeration.

Now we report on the synthesis and characterization of new Ni-Sn alloy/reduced graphene oxide composite coatings from choline chloride based ionic liquids on Cu substrates. Different electrodeposition parameters have been investigated such as: the influence of direct and pulse current, current density, the ratio between Ni (II) and Sn (II) salts in choline chloride-ethylene glycol and others. The obtained composite deposits are adherent and uniform onto copper substrates. SEM, Raman and XRD analysis evidenced the successful insertion of reduced graphene oxide into the metallic Ni-Sn alloy matrix.

To evaluate the corrosion performance, several accelerated corrosion tests have been performed, respectively: (i) continuous immersion in 0.5M NaCl for 360 hours with intermediary visual examinations and recording of corrosion potential; (ii) potentiodynamic polarization curves and (iii) impedance spectra at open circuit potential, in 0.5M NaCl, using a PARSTAT 4000 potentiostatic equipment. The corrosion performances are discussed taking into account the applied electrodeposition procedures.

Acknowledgements: This project has received founding from the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No764977.

RICCCE 2019, Mamaia

Abstract

Electrodeposition of Ni-Sn Alloy/rGO Composite Coatings Involving Choline Chloride Based Deep Eutectic Solvents

Sabrina Patricia Rosoiu1, Aida Ghiulnare Pantazi1, Aurora Petica1, Anca Cojocaru1,2, Stefania Costovici1, Teodor Visan1,2, Liana Anicai1, Marius Enachescu1

1Center of Surface Science and Nanotechnology, University Politehnica of Bucharest, Splaiul Independentei 313, Bucharest, 060042, Romania

2Department of Inorganic Chemistry, Physical Chemistry and Electrochemistry, University Politehnica of Bucharest, 132 Calea Grivitei, Bucharest, Romania, 010737, Bucharest, Romania

e-mail address: lanicai@itcnet.ro

Graphene related materials attracted considerable attention in the recent years and they showed great potential in the electronics field owing to their superior mechanical properties and electrical and thermal conductivities. The addition of graphene to the binary Sn alloys may contribute to the accommodation of the large volume change of Sn during cycling process when they are used as anodes of Li ion batteries or may contribute to the mitigation of whiskers growth when applied in electronic interconnections [1].

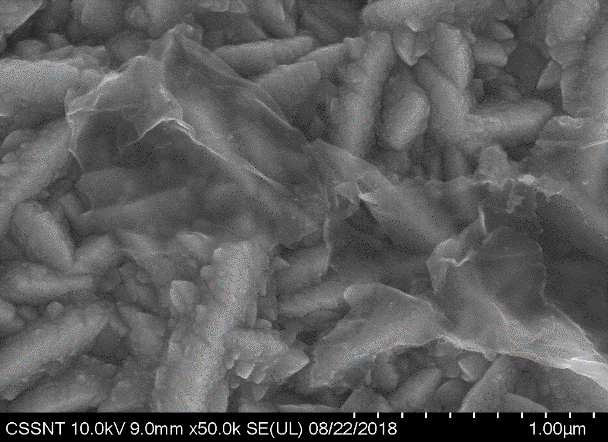

Therefore, the present paper presents several experimental results regarding the electrodeposition and characterization of Ni-Sn alloy composites with reduced graphene oxide (rGO) coatings using choline chloride based deep eutectic solvents (DESs). These types of electrolytes possess good air and water stability, are recyclable and non-hazardous to human health. In addition, they allow for excellent dispersibility of carbon nanomaterials including rGO without additional surfactants for relatively long periods of time [2]. Electrolytes containing Sn (II) and Ni (II) salts in choline chloride-ethylene glycol eutectic mixtures (Sn:Ni molar ratio in electrolyte between 1:1 – 3:1) with additions of 0.1-0.5 g/L ammonia functionalized graphene oxide have been used. The obtained composite deposits are adherent and uniform onto Cu and mild steel metallic substrates, with thicknesses of about 10-12 µm at 30-40 mA/cm2 for 30 min. under ultrasound stirring. The use of pulsed current was found to facilitate a better incorporation of rGO within the Ni-Sn alloy matrix as compared to direct current. SEM, Raman, XPS and XRD analysis evidenced the successful insertion of reduced graphene oxide into the metallic Ni-Sn alloy matrix (see Fig.1).

Fig.1 SEM micrograph of Ni-Sn alloy / reduced graphene oxide composite coating ( 20 mA/cm2, pulsed current),

ton = toff = 100 ms, 30 min., 65oC)

The corrosion performance of the obtained alloy composite coatings in 0.5M NaCl solution at room temperature is also discussed taking into account the applied electrodeposition procedures.

Acknowledgements: Part of this work was supported by Romanian Ministry of Education and by Executive Agency for Higher Education, Research, Development and Innovation Funding, under NOVTINALBEST project 38/2016, M Era Net Program. S.P. acknowledges the financial support under the Marie Skłodowska-Curie grant agreement No764977.

References:

[1] Y.Tong, S. Bohmb, M. Song, Graphene based materials and their composites as coatings, Austin J. Nanomed. Nanotechnol. 1(1), 1003, 2014.

[2] N. Liu, F. Luo, H. Wu, Y. Liu, C. Zhang, J. Chen, One-Step Ionic-Liquid-Assisted Electrochemical Synthesis of Ionic-Liquid-Functionalized Graphene Sheets Directly from Graphite, Adv. Funct. Mater. 18, 1518–1525, 2008.

Electrochem 2019, Glasgow

Abstract

Electrodeposition of Ni-Sn alloys and Ni-Sn / rGO composite coatings from deep eutectic solvents and their physicochemical characterization

Sabrina Patricia Rosoiua, Aida Ghiulnare Pantazia, Aurora Peticaa, Anca Cojocarua,b, Caterina Zanellac, Marius Enachescua Stefania Costovicia, Teodor Visana,b, Liana Anicaia

aCenter of Surface Science and Nanotechnology, University Politehnica of Bucharest, Splaiul Independentei 313, Bucharest, 060042, Romania

bDepartment of Inorganic Chemistry, Physical Chemistry and Electrochemistry, Faculty of Applied Chemistry and Materials Science,University Politehnica of Bucharest, Calea Grivitei 132, Bucharest, 010737, Romania

c Department of Materials and Manufacturing, School of Engineering, Jönköping University, Gjuterigatan 5, 553 18 Jönköping, Sweden

Electrodeposited Ni-Sn alloys show enhanced characteristics compared to those of the individual elements. They represent an alternative to chromium decoration and they find applications in corrosion protection due to their good anticorrosive properties. In addition, Ni-Sn alloys are used in electronics as etch resist in printed board circuits as well as in automotive industry. Recently, they have been also investigated as anode material in lithium ion batteries. Furthermore, graphene related materials are attracting the current interest owing to their unique electrical, thermal and mechanical properties.

The electrodeposition of Sn based containing alloys from aqueous electrolytes is limited by the oxidation of Sn2+ to Sn4+ and sludge formation which leads to the solution destabilization. Deep eutectic solvents (DESs), defined as eutectic mixtures of cholinium salts with hydrogen bond donor compounds, represent a promising green alternative to overcome this problem and due to their high viscosity, they may act as dispersants of carbon-based materials.

Here we report the synthesis and characterization of both Ni-Sn alloys and of Ni-Sn/reduced graphene oxide composite coatings from choline chloride based ionic liquids DESs on Cu substrates. Influence of different electrodeposition parameters has been investigated including: the use of direct and pulsed current, the applied current density value and the ratio between Ni (II) and Sn (II) metallic species in choline chloride-ethylene glycol eutectic mixture as solvent. The obtained deposits coatings are adherent and uniform onto copper substrates. SEM, Raman and XRD analysis evidenced the successful insertion of reduced graphene oxide into the metallic Ni-Sn alloy matrix.

Finally, the mechanical properties and conductivity have also been investigated.

Acknowledgements: This project has received founding from the European Union’s Horizon 2020 research and innovation programme under the Marie Skłodowska-Curie grant agreement No764977.

The PhD student expresses her appreciation to the Department of Materials and Manufacturing of Jönköping University for their kind permission to use the laboratories systems.

Regional Symposium on Electrochemistry of South-East Europe 2019, Split

Abstract

Electrodeposition of Ag and Ag composites with carbon nanotubes using novel deep eutectic solvent formulations

Sabrina Rosoiu1, Aurora Petica1, Aida Ghiulnare Pantazia, Marius Enachescu1, Teodor Visan1,2, Liana Anicai1

1Center of Surface Science and Nanotechnology, University Politehnica of Bucharest, Splaiul Independentei 313, Bucharest, 060042, Romania

2Department of Inorganic Chemistry, Physical Chemistry and Electrochemistry, Faculty of Applied Chemistry and Materials Science, University Politehnica of Bucharest, 132 Calea Grivitei, Bucharest, Romania, 010737, Bucharest, Romania

*Presenting author’s email: sabrina.rosoiu@cssnt-upb.ro

The paper presents some experimental results regarding the electrodeposition and characterization of Ag and Ag composites with carbon nanotubes involving choline chloride based ionic liquids, also known as “deep eutectic solvents” (DES). The influence of applied current form, respectively of direct current vs. pulsed current on the deposit appearance and carbon nanotubes incorporation is also discussed.

Generally the experiments showed a difficulty to electrodeposit the Ag layer mainly due to the instantaneous nucleation process that determines the formation of a powdery deposit which further impedes a suitable adhesion. Under these circumstances, a novel DES electrolyte was proposed, consisting in choline chloride-triethanolamine (IL-TEA)eutectic mixture (1:1 molar ratio) sometimes also containing 0.1 M nicotinic acid (NA). Dispersion stability of multi-walled carbon nanotubes (MWCNTs) was found to be excellent in the used eutectic solvent. According to Raman, XPS and XRD analysis, the carbon nanotubes were successfully inserted into the metallic matrix, being also favourized by the use of pulsed current.

Metallic light grey coatings, with a good adherence and uniformity onto the Cu substrate have been obtained at a working temperature of 70-80oC and current density values between 2 -5 mA/cm2. XRD pattern suggested a good crystallinity of the Ag layer. The crystallites average sizes of 28-35 nm have been determined using the Scherrer equation.

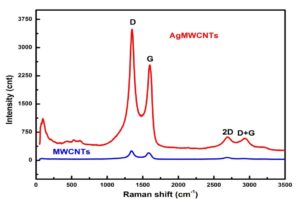

For Ag-MWCNT composites, the Raman scattering intensities for the D and G bands of MWCNTs are significantly enhanced as compared to those of pure MWCNTs (see Fig.1), suggesting a potential use as a surface enhanced Raman scattering (SERS) substrate.

Figure 1 – Raman spectra of Ag-MWCNT composite coating and commercial MWCNTs

Acknowledgements: The work was supported by Romanian Ministry of Education and by Executive Agency for Higher Education, Research, Development and Innovation Funding, under NOVTINALBEST project 38/2016, M Era Net Program and under ROFCC project, Contract No. 25 PCCDI/2018. S.P. acknowledges the financial support under the Marie Skłodowska-Curie grant agreement No764977.

Multi- Functional Nano-Carbon Composite Materials 2018, Bucharest

Abstract

Morphological and structural investigations of electrodeposited Ni-Sn alloy/reduced graphene oxide composites from deep eutectic solvents

S. P. Rosoiu, A. Ghiulnare Pantazi, A. Petica, A. Cojocaru, S. Costovici, T. Visan, L. Anicai, M. Enachescu

a. Center of Surface Science and Nanotechnology, University Politehnica of Bucharest, Splaiul Independentei 313, Bucharest, 060042,

Romania

b. Department of Inorganic Chemistry, Physical Chemistry and Electrochemistry, Faculty of Applied Chemistry and Materials Science,

University Politehnica of Bucharest, 132 Calea Grivitei, Bucharest, Romania, 010737, Bucharest, Romania

*Corresponding author’s email: liana.anicai@cssnt-upb.ro

In recent years, graphene related materials attracted considerable attention and they have great potential in the electronics field owing to their superior mechanical properties and electrical and thermal conductivities.

The addition of graphene to the binary Sn alloys may contribute to the accomodation of the large volume change of Sn during cycling process when they are used as anodes of Li ion batteries or may contribute to the mitigation of whiskers growth when applied in electronic interconnections. The use of ionic liquids in general and of choline chloride based ones in particular was found to be suitable media to form stable graphene based dispersions overcoming the agglomeration problems [1-3].

The present paper presents several experimental results regarding the morphological and structural characterization of Ni-Sn alloy/reduced graphene oxide composite coatings from choline chloride based ionic liquids on Cu substrates. Electrolytes containing Sn (II) and Ni (II) salts in choline chloride-ethylene glycol eutectic mixtures (Sn:Ni molar ratio in electrolyte between 1:1 – 3:1) with additions of 0.1-0.5 g/L ammonia functionalized graphene oxide have been used, showing a very good dispersability and stability for more than 96 h. The obtained composite deposits are adherent and uniform onto metallic substrates, with thicknesses of about 10-12 μm at 30-40 mA/cm2 for 30 min. under ultrasound stirring. SEM, Raman, XPS and XRD analysis evidenced the successful insertion of reduced graphene oxide into the metallic Ni-Sn alloy matrix. Atomic Force Microscopy (AFM) investigations to get more details on the local morphology features are also discussed.

Acknowledgements: The work was supported by Romanian Ministry of Education and by Executive Agency for Higher Education, Research, Development and Innovation Funding, under NOVTINALBEST project 38/2016, M Era Net Program

[1] Y.Tong, S. Bohmb, M. Song, Graphene based materials and their composites as coatings, Austin J. Nanomed. Nanotechnol. 1(1), 1003, 2014.

[2] N. Liu, F. Luo, H. Wu, Y. Liu, C. Zhang, J. Chen, One-Step Ionic-Liquid-Assisted Electrochemical Synthesis of Ionic-Liquid-Functionalized Graphene Sheets Directly from Graphite, Adv. Funct. Mater. 18, 1518–1525, 2008.

[3] M.H. Chakrabarti et al., One-pot electrochemical gram-scale synthesis of graphene using deep eutectic solvents and acetonitrile, Chem.Eng.J. 274, 213–223, 2015.